oilanalysis

oilanalysis

Oil analysis (OA) is the laboratory analysis of a lubricant's properties, suspended contaminants, and wear debris. OA is performed during routine preventive maintenance to provide meaningful and accurate information on lubricant and machine condition. By tracking oil analysis sample results over the life of a particular machine, trends can be established which can help eliminate costly repairs.

Our large laboratory database of original lubricants are assured that the ordered product is available in the delivered package. Furthermore, we are, with our manufacturers, directly deeply involved in the manufacturing process to the customer. This practical experience has been used for decades with our advice lubricant directly to the machine. Oil analyzes are "assistance systems" that only give a hint.

In addition to monitoring oil contamination and wear metals, modern usage of OA includes the analysis of the additives in oils to determine if an extended drain interval may be used. Maintenance costs can be reduced using OA to determine the remaining useful life of additives in the oil. By comparing the OA results of new and used oil, a tribologist can determine when an oil must be replaced. Careful analysis might even allow the oil to be "sweetened" to its original additive levels by either adding fresh oil or replenishing additives that were depleted.

The early detection of unusual mechanical wear and lubricant deterioration can save costly disasters that basic maintenance programs cannot prevent. We strive on preventing these issues.

Collecting an oil sample, it is important to ensure that procedures are used to minimize disturbance of the sample during and after the sampling process. Oil samples are typically drawn into a small, clean bottle which is sealed and sent to a laboratory for analysis.

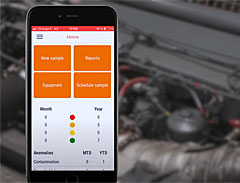

Monitoring the state of the lubricating oil is one of the most important maintenance. HLAS helios oil analyzes provide information about the state of the machine, engine or system, information on maintenance intervals and give early warning to possible upcoming repairs or unusual stress and wear. The guiding lower spending through anticipatory repair or part replacement and less costly downtime and downtime by knowing and planning from the HLAS oil analysis data. With HLAS helios oil analysis will extend the life of drives and power systems that utilize repair cycles optimally, reduce your risks by unforeseeable damage and put your engine, transmission and hydraulic oil efficiently. Despite all the oil analysis there is no 100% security. In mineral lubricating oils you have a slightly longer period to respond, with the more widespread use of synthetic lubricating fluids, the reaction time is short.

For gas engine oil analyzes a quick HLAS oil analysis is important because the service life depending on fuel / gas insert can be shortened. HLAS Helios Lubricant (lubricant) analysis system for industrial, marine, yachts, ocean-going vessels, Tansformatorenöle, turbine oils, gas engine oils and more.

Machinery scaffolding and posing, plant and maintenance service

Important Information: Delivery in the customer's own bottles and containers to be with € 75, - will be invoiced net and disposal, plus VAT, each container.

We will be happy to answer any questions or provide you with individual offers.

Phone product advice: +49 (0)40 53798 5515

You prefer to write?

As a brand partner of leading lubricant manufacturers, you can order here safely and directly from the source.

At any time current prices and availability at: https://schmierstoffe.kaufen/gb/

Visit our shop